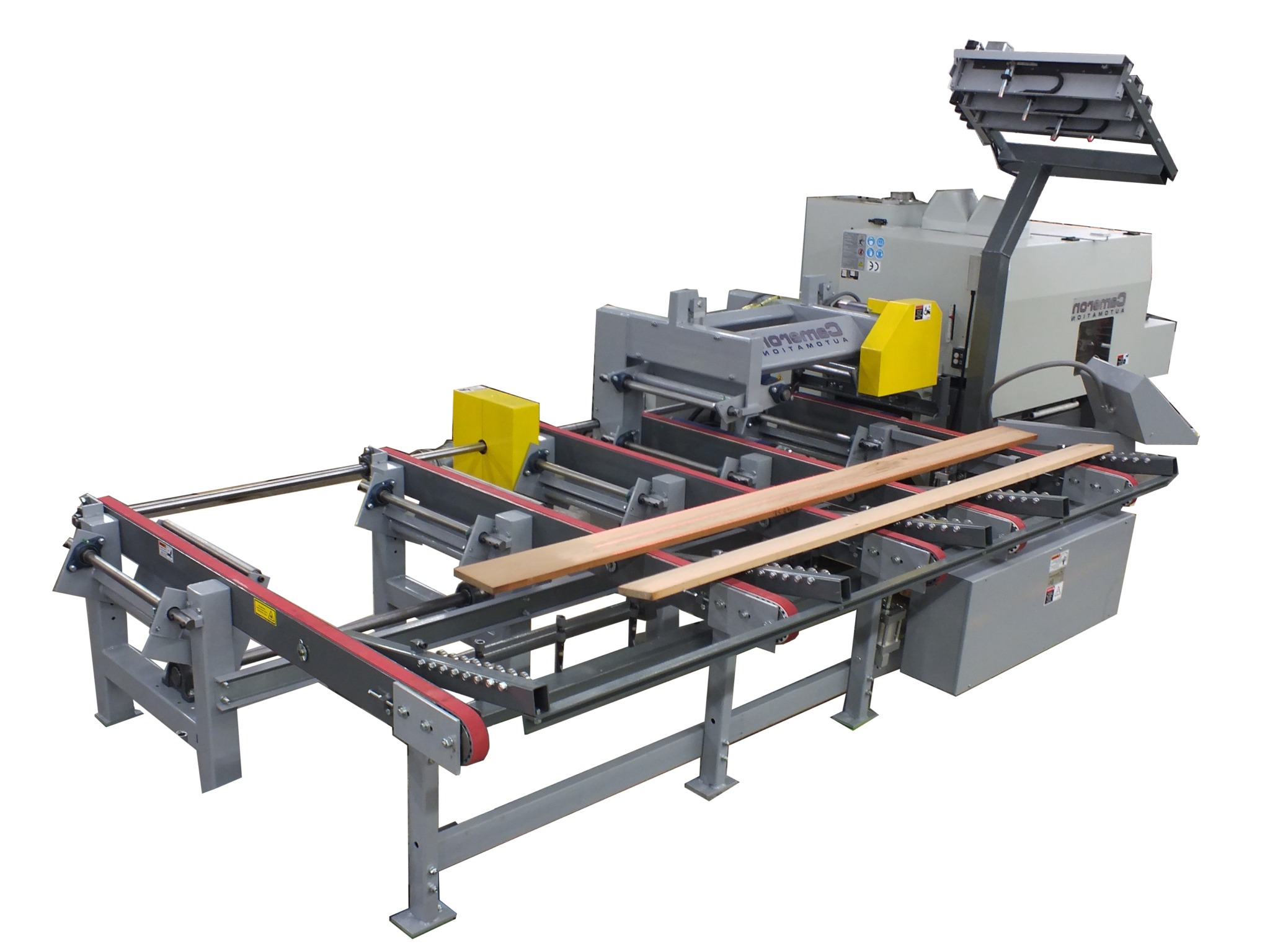

The Quick Rip System offers the highest yield in the market due to its fenceless design, powerful “Opti-Rip” optimizing software, and multiple moving blade technology in a few different model saws. Non straight boards are handled just as effectively as straight boards and the net result is lower raw material costs.

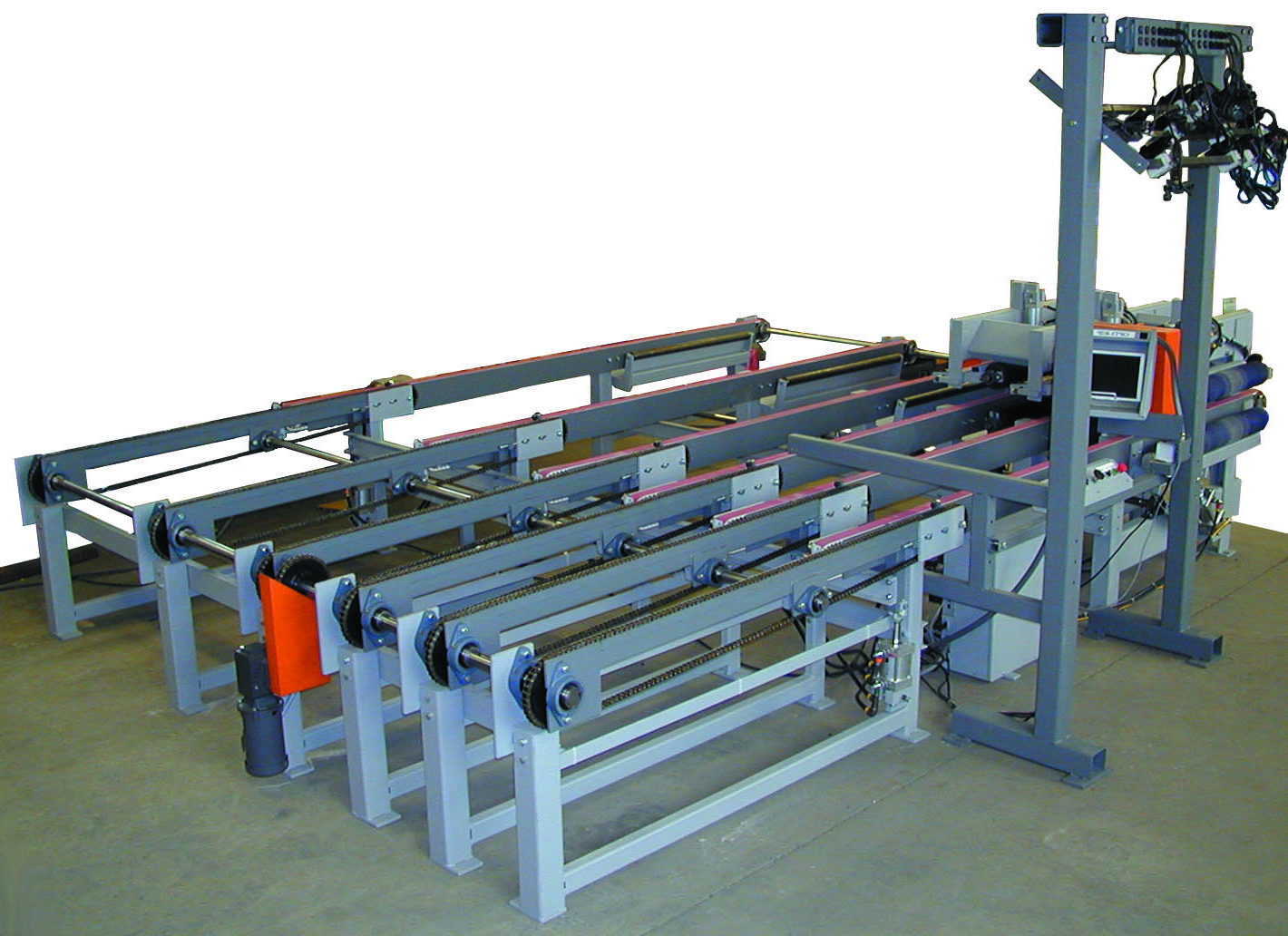

- Cameron Quick Rip Infeed with Fenceless, Servo-Driven Board Positioner with Extremely High Accuracy

- Multiple Moving Blade, Multiple Fixed Blade Setups

- Completely Integrated Software Package

- Automatic Movable Blade Positioning by the Cameron Software

- 市场上最高的板收益!!!

卡梅隆锯模型:

- #413A – 12″ Wide (2) Moving Blade, Multiple Fixed Blade Saw

- #413B – 18″ Wide (3) Moving Blade, Multiple Fixed Blade HD Rip Saw

- #413C – 24″ Wide (4) Moving Blade, Multiple Fixed Blade HD Rip Saw

不像其他系统, the Quick Rip is fenceless and has Auto Skewing for achieving highest possible yield. Our sensors read the width, the length, and the shape of the boards. 如果板有弯曲或锥度, our software can determine if the board should be skewed for higher yield. 如果是,它会自动发生. This adds up to an additional 3% yield over systems with a fence. Quick Rips can be paired with Moving Blade Saws that come with (2), (3) or (4) Moving Blades Depending on your Cut Bill and Lumber. The Cameron Opti-Rip software is written in-house allowing changes, improvements and free upgrades to happen on a regular basis.